Industrial Machining

Industrial Machining

Associate of Applied Science Degree, Certificates

Available at: Windward Campus

Program Overview

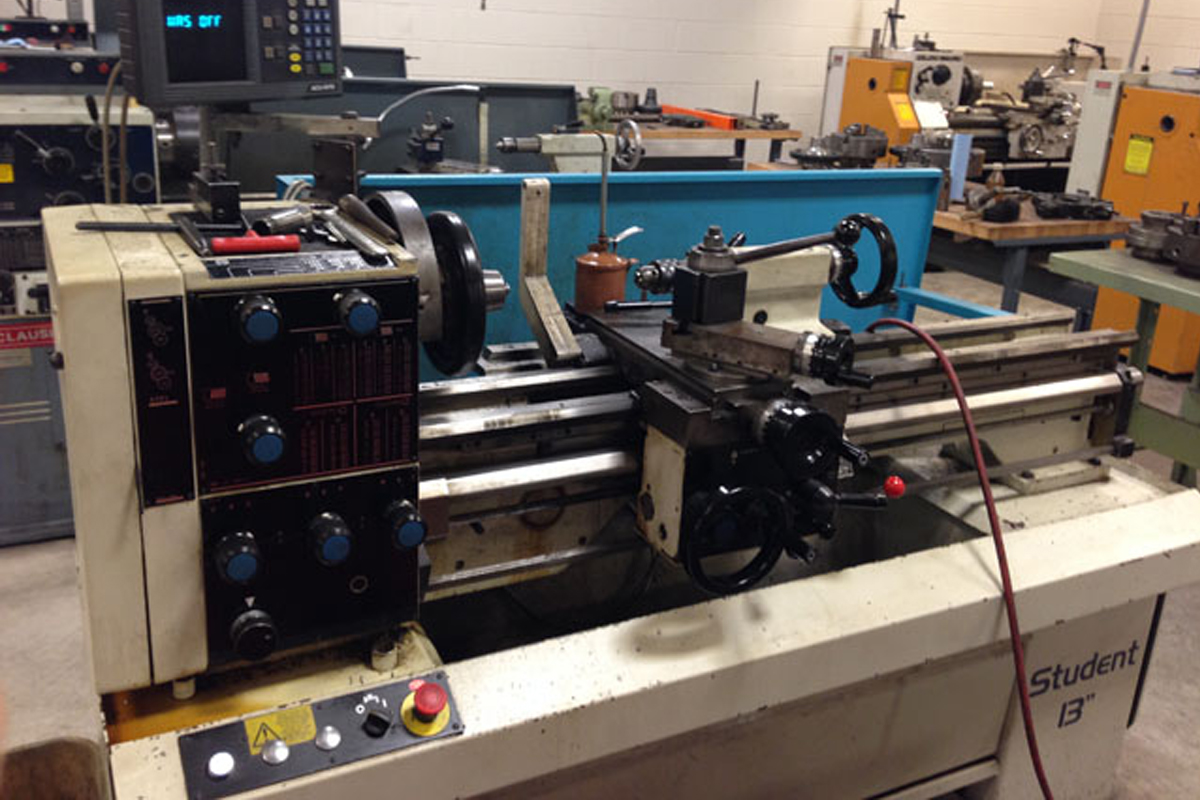

A machinist operates machine tools to produce precision metal parts by the action of a cutting tool against a revolving material or the material may be secured in a vise and special fixture and the cutting tool revolves or reciprocates as it removes metal shavings from the material. The cutting tool selected must always be harder and tougher than the material to be cut. Machinist students gain experience on the basic chip producing machine tools such as drill presses lathes, vertical and horizontal milling machines, cylindrical and surface grinders. As they operate the machine tools they acquire knowledge of the properties and behavior of steels, cast irons, aluminums, brasses, and other exotic materials which enables them to be able to meet all of the part specifications such as threads, slots, holes diameters, and shoulders, which the quality department must compare to the drawing and approve or reject. Producing a part will often require several steps and more than one type of machine tool. Calculations must be determined as to the cutting speeds and chip loads for the material to be machined.

The parts produced may be one of a kind or large number production runs which are repetitive in nature. The job requires stamina because machinists stand most of the day and may be required to lift moderately heavy work pieces and machine tool accessories.

Mathematics and blue print reading skills are essential to become a machinist or a CNC programmer. Many machines today are computer numerically controlled (CNC), which means that the machine tools must be programmed and tools set in place by the machinist before cutting takes place. CNC machines enable machinist to be more productive and produce parts with a speed and level of precision that is not always possible with traditional machining techniques. Furthermore, because precise movements are recorded in the program, they allow this high level of precision to be consistently repeated.

Curriculum

Students planning to continue at a senior college should consult an advisor concerning degree requirements of the college to which transfer is intended.

- Industrial Machining Applied Technology, Associate of Applied Science

- Industrial Machining Applied Technology - Level II, Certificate

- Job Shop Machining - Level I, Certificate

- CNC Machining - Level I, Certificate

Careers

Page last updated September 16, 2022.